WHY ATTEND

October 18–19, 2023 · Santa Clara, CA

A Rapidly Expanding Sector

The robotics sector continues to expand rapidly, with new products, services and companies continually emerging, and supporting an ever-increasing range of applications across the consumer, commercial, industrial and civil markets. Ongoing technological advances, increasing levels of investment, and ongoing business and social need, ensures that opportunities will continually become available to create wholly new products and services.

The Role of Innovation

Questions remain, however, as to which products, services and markets present the greatest opportunities, the fewest challenges and the least risk, and what are the latest technical solutions and approaches available to the engineering community to deliver on them. This speaks to the issue of innovation, which for robotics companies is the most critical determinant of long-term competitiveness. But business practices and processes, too, can be sources for innovation in areas such workforce development, funding and investment, protecting intellectual property, and much more.

The Robotics Business Development Event

Since its founding in 2004, the RoboBusiness Conference & Expo has grown and evolved to become the world’s premier robotics business development event. During those intervening years, the robotics sector, too, has experienced a great deal of change and undergone dramatic growth, some attributable to the RoboBusiness event itself.

As we enter the second decade of the 21st century, RoboBusiness will continue to play a critical role as a leading driver for the international robotics sector. To better serve RoboBusiness attendees, as well as accelerate the robotics sector as a whole, RoboBusiness has been reimagined and reworked, retaining the best aspects of past events, but now with a greater singularity of purpose… to highlight robotics and business ‘innovation’ in all its forms, and to identify and prioritize the best commercial opportunities going forward.

Identifying Opportunities, Driving Business, Accelerating the Robotics Sector

RoboBusiness provides a unique and unparalleled forum for the global robotics sector to come to together to exchange information, share best practices, and uncover new opportunities for the benefit of those developing new robotics products, technologies and services for sale to others, or for their own internal use. It also serves the needs of those companies pursuing investment, providing funding and seeking partnerships. RoboBusiness 2020 highlights include:

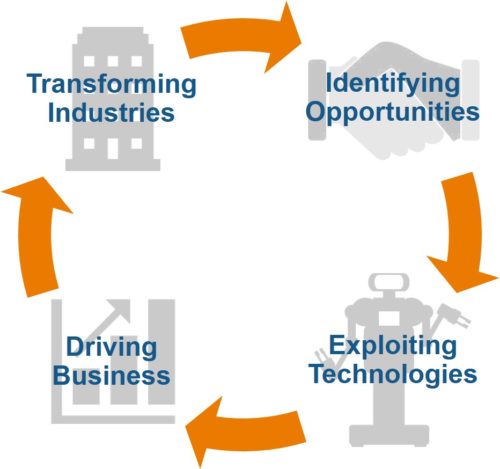

- Actionable Content – Thought leaders from around the world will deliver keynotes and general sessions specifically designed to impart to business and engineering professionals the information they need to identify market opportunities, successfully develop and deploy the next generation of commercial robotics systems, and accelerate their businesses. Speakers will share their expertise on a variety of topics in four tracks:

- Identifying Opportunities Track

- Exploiting Technologies Track

- Driving Business Track

- Transforming Industries Track

- Leading Companies – The RoboBusiness expo floor provides attendees with numerous opportunities to meet with the leading providers of cutting-edge robotics enabling technologies, as well as the latest robotics products and business services.

- Special Events & Networking Opportunities – At RoboBusiness Conference & Expo, attendees can meet with their industry peers during special events and other networking opportunities to celebrate successes, share insights, and discuss business opportunities and partnerships.

- Co-located With DeviceTalks and Field Robotics Engineering Forum – RoboBusiness is co-located with DeviceTalks, the premier industry event for medical technology professionals, as well as the Field Robotics Engineering Forum (FREF). Robotics Summit attendees will have open access to the DeviceTalks and FREF show expo floor and vice versa.

Resources

Advertise with us

For registration or logistic questions, contact events@wtwhmedia.com

Sponsorship Opportunities

Colleen Sepich

Events Sales Director

csepich@wtwhmedia.com

857-260-1360

Heather Herbert

Event Sales Manager

hherbert@wtwhmedia.com

512.760.0570